Limex foam units and the effect of Menno Florades foam

Limex has developed unique foam units that foam up Menno Florades

Hygiene is essential in breeding operations. Cultivation trays, harvest boxes and CC containers should be disinfected to keep the starting material safe. Menno Florades is a widely used, effective disinfectant for cultivation. By foaming, we significantly increase the effectiveness of the disinfectant.

Limex has developed unique foaming units that foam Menno Florades. These units enrich your existing machine and optimize the washing process.

Foaming trays and crates with the disinfectant Menno Florades

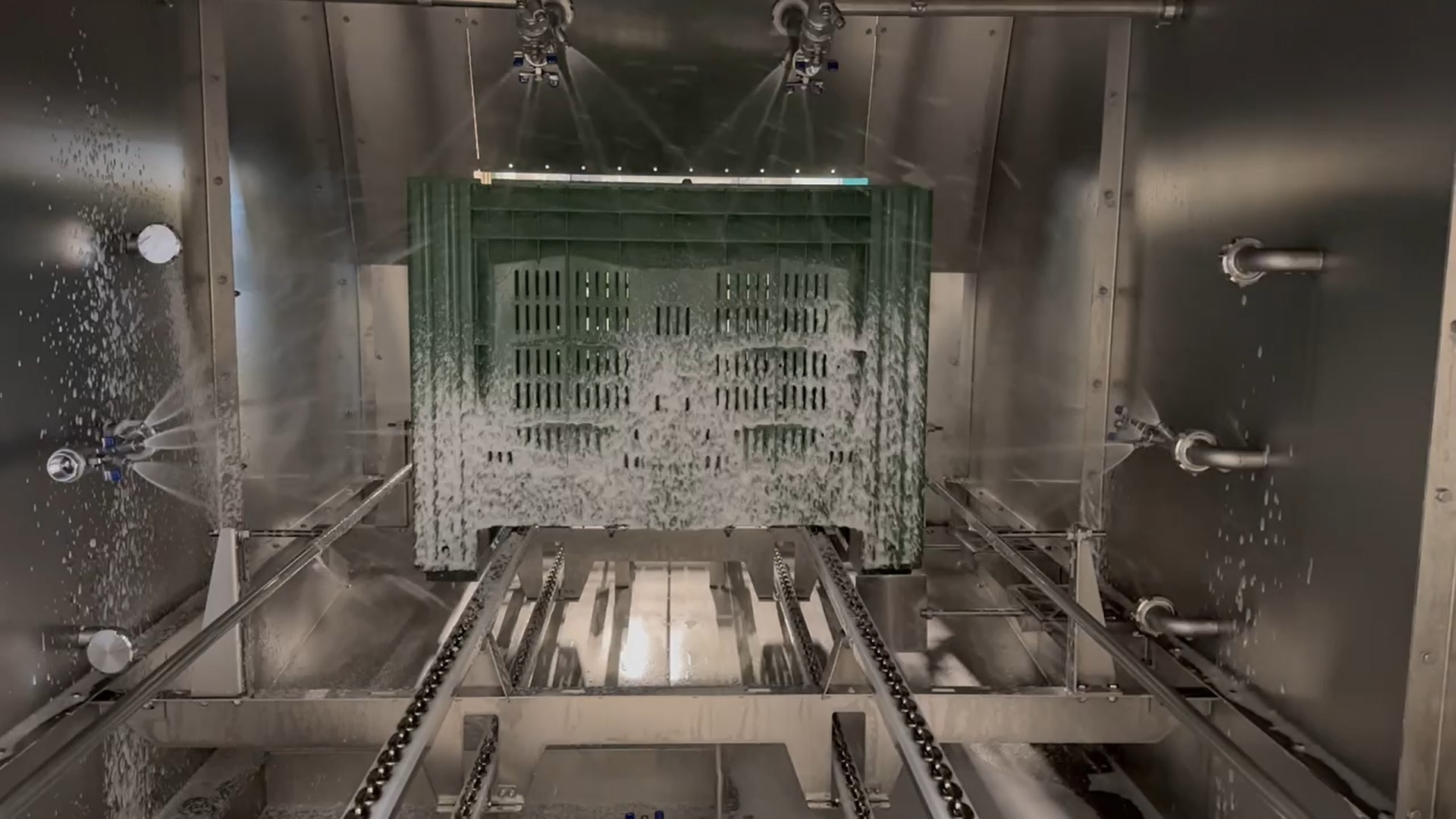

In this video you can see a crate washer and a foaming unit. Crates and small plastic trays are foamed. In this video, the capacity is only a few hundred crates per hour, but larger capacities are of course also possible. Growing trays and growing containers pass through the same machine.

Disinfection of big boxes with Menno Florades in foam form

This video shows a washing system for cubic boxes and a foam unit. The new foam technology makes it possible to apply a high-precision layer of foam to the entire surface of the crate. The capacity of this installation is 50 to 100 crates per hour. These machines are currently being integrated into a fully automated crate processing line. When this installation is put into operation, we will be happy to publish the images in our network. This is expected to be the case in the 4th quarter of 2024.

Optimum disinfection of CC containers with foam from Menno Florades

Plant trolleys, e.g. CC containers, are also foamed by the Limex foam units. We are talking about capacities of up to 100 trolleys per hour. In the video below, the trolleys are first washed and then foamed. A CC container can hold up to 30 panels. These compactly stacked trolleys pose no challenge for our foam units.

Why “precision foaming” with a Limex foaming unit?

- More effective disinfection due to extended contact time

- The disinfectant stays on the surface longer thanks to the foam

- Precise dosing of the disinfectant

- Lower consumption to reduce environmental impact and consumer costs

- Closed layer thicknesses on all possible surfaces, including CC containers

- Can be combined with Limex washing systems in one line

- Unique precision foaming technology

- Start-stop function can be activated when no products are present

- Other products can also be foamed

- Practical development

- Solid construction for years of use

Foam application extends the contact time of the disinfectant

Applying the disinfectant in foam form significantly extends the contact time between the active ingredient and the product surface. A liquid disinfectant flows off quickly, so the surface dries quickly. Foam, on the other hand, stays on the surface longer than liquids. This extends the contact time with the chemical, enabling significantly better disinfection. As a result, the concentration of disinfectant can be reduced. This in turn means less environmental pollution and lower consumption costs.

Menno Florades

Menno Florades is a widely used product for plant breeders and seed developers. The product is certified as a crop protection product and has an N number with biocide approval. We therefore know that it complies with laws and regulations.

Menno Chemie Vertrieb GmbH, the manufacturer of Menno Florades, has carried out numerous laboratory tests on the effectiveness and contact time against bacteria, fungi and viruses. Both Menno Chemie Vertrieb GmbH and Royal Brinkman will be happy to provide you with more information.

Clean first, then disinfect

Disinfectants are extremely effective on the surfaces of products such as crates, growing trays and trolleys. However, any contamination of this surface has a very negative effect on the effectiveness of a disinfectant.

Microorganisms hide in and under these organic contaminants. It therefore makes little sense to treat contaminated products with a disinfectant. We therefore strongly recommend cleaning the products first before treating them with a disinfectant. This is also the case with foam disinfection. Clean first and then disinfect.

The development of precision foaming

The first Limex foaming unit was installed at a seed developer in the south of the Netherlands in 2017. The foam was applied in large quantities, causing excess foam to drip off the trays. The excess foam was collected, reused via a circulation system and reapplied to the products. However, over the course of the day, the effectiveness of the circulating foam decreased due to various external influences. The concept was rigorously revised and this resulted in the current generation of foam units. We call these foam units, which offer many more possibilities, ‘precision foaming’.

The latest foam units from Limex apply a layer of foam to the surface of the products with high precision. The thickness of the foam layer can be adjusted and adapted to the needs of the user. If no products enter the machine for a certain period of time, the foaming system switches off and switches back on automatically at the right time.

Tens of foam units in use, interest is growing

Around 25 foam units are now successfully in use in the Netherlands and Germany. There is lively interest from other countries such as Italy, Mexico, Scandinavia and America.

Foaming with other products (sterile from L.G. Italia S.R.L.)

Various disinfectants are available on the market – often in foam form. In collaboration with L.G. Italia, Limex has tested the Steril disinfectant liquid several times. By adjusting certain parameters, Steril can also be used in foam units.

Limex is constantly looking for other ways of foaming. There are many possibilities. Contact our sales colleagues and discuss the possibilities with us.

Other options for increasing disinfection effectiveness

We will be happy to inform you about additional precautions to increase the disinfection effect.

- The contact time is extended if the foamed products are stored in a draught-free, protected location. Logically, the foam dries faster in the sun and wind than in a closed storage facility.

- Extend the contact time by sealing stacks of products with foil. This will keep the products moist for longer.

- Place the treated products in a clean, closed warehouse. Prevent pests (such as birds, mice and rats) from re-contaminating the clean products.

Acid attacks concrete

Various disinfectants, including Menno Florades, are acidic. Acid attacks the concrete. Make sure that the floor around the foam unit and when storing products is protected from the effects of acid. For example, consider a floor coating or acid-resistant concrete.

Interested in foam units?

Request a quote, send a Whatsapp message or fill out the form for more information. We are happy to think with you.

Quick contact?

Send a mail to sales@limex.nl, call us at 0773074412 or leave your details and we will contact you soon.

A peek into our world

Are you curious about what it's like for us? Then take a peek into our world.