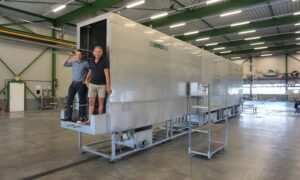

Industrial tray washing machines

Clean seed trays are essential for healthy products and higher profits. As a grower, of course you want to minimise the risk of contamination by bacteria, viruses and fungi, which makes good hygiene is very important.

Our expertise in industrial tray washers is at your disposal

Cleaning with a Limex tray washer ensures that your trays meet the strictest hygiene and food safety requirements. With our specialist knowledge and extensive experience, we can tailor our tray washers specifically to your crops. This reduces the risk of contamination considerably and immediately results in less spoilage and higher net yields. After all, you’ve already made the investment into inputs such as energy, water, raw materials, seeds and labour;

Choosing Limex means choosing a sustainable solution. Our machines reduce water, energy and chemical consumption. The Limex industrial tray washer removes organic soiling and eliminates contamination by bacteria, viruses and fungi. This results in less spoilage, and higher yields from the same investment in raw materials and labour.

Other advantages of a Limex tray washer

- Especially for heavy soiling caused by substrate, potting soil and sharp sand;

- Capacity from 100 to 2,000 trays per hour;

- Eliminates fungi such as Fusarium, Phytopthora, and Pythium;

- Eliminates viruses such as ToBRFV and CGMMV (Limex research 2020) or TVX (Limex research 2017)

- The modular design allows washing lines to be extended flexibly;

- Robust construction, easy to keep clean, and low-maintenance;

- High residual value on the second-hand market even after years of use. If you’re looking for a used tray washer, check out this page: ‘Used machines’

Possibilities of our industrial tray washers

- High-pressure units, for example for pre-rinsing Pressure is adjustable to minimise water and energy consumption;

- Adds foaming disinfectant (Menno Florades) for longer exposure time to the disinfectant;

- Blow off to remove excess water;

- Heated by heat exchanger, electricity, or steam injection;

- Measures the concentration of cleaning agents or disinfectants, and doses automatically if necessary;

- Renting machines: the perfect solution for seasonal products;

- Modified power supply for international customers.

- Additional filter technology to recirculate the water intensively.

Our tray washers at customers

Tray washing machines from Limex help keep the quality of your crops and products consistently high. Our other machines are also used successfully by various customers, both large and small:

- Washing and foaming with Menno Florades at HS Schneider Kunzelsau, Germany;

- Washing seed trays at WPK Made, the Netherlands;

- Washing seed trays at De Koster, Belgium;

- Washing nursery trays at Svenska Skogsplantor, Sweden (5th machine delivered in 2021);

- Washing seed trays and planters at Ontario Plants Propagation, Canada;

- Washing rafts and floats at Tanimura and Antle Tennessee, United States;

- Washing and disinfecting seed trays at Hishtil, Israel;

- Washing rafts and floats for PlantLab, Amsterdam and PlantLab, USA; Washing and foaming at Jungpflanzen Gernert in Albertshofen, Germany.

Sinner’s Circle

Professor Sinner described and visualised the physical principle behind cleaning many years ago in his Sinner’s Circle. It explains how getting the balance between these factors right gives the best cleaning result. These factors are: mechanical action (water pressure and flow), time, temperature and chemical action. The four factors need to be balanced properly for maximum efficiency. Our engineers design the tray washers so they are perfectly balanced in accordance with the Sinner’s Circle principle.

Questions?

Would you like to know more about all the options of our industrial tray washers and how we can help you protect your valuable harvest? Please feel free to contact us.