Powerful synergy of two family businesses: VHM and Limex cooperate on engineering a washing line for 1 m³crates

Something special happens when two business come together and each can contribute a missing puzzle piece. When both parties have an intuitive understanding and can solve the puzzle together, synergy is created and the result is a whole that is greater than the sum of its parts. This is precisely what happened when Limex and VHM Machinery decide to partner up.

VHM is specialised in automating material handling and logistics processes of 1 m³crates , storage bins and big bags. Rik van Hees, managing director and owner of VHM, explains: “Our focus is not on the actual products, but on the processes of filling, emptying, turning, conveying and more.” Limex specialises in crate washing and disinfection machines. These two specialisms have now been combined in an exceptional project.

On the same line… (crate washing line)

Limex and VHM have been familiar with each other for some time, but had not collaborated on a project before. When Limex received a request from a major seed breeder in the Dutch Westland region, they joined forces. The request was for a solution that could wash, foam disinfect, stack and buffer crates fully automatically. The customer wanted a single line, with Limex as the contact. “A one-stop shop, to provide the customer with a full-service experience” says Joep Janssen, owner of Limex. “This gives customers a single point of contact for all their lines.” However, behind the scenes, the inventivity of both companies was combined.

Washing, foaming and handling crates

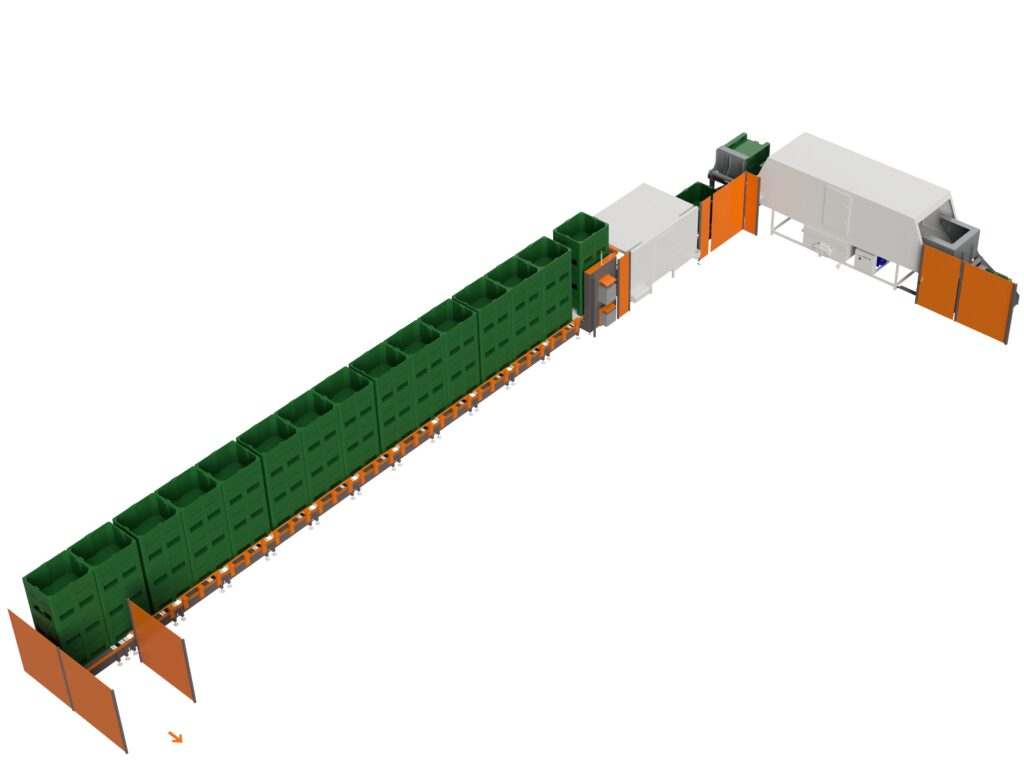

The two specialists engineered a single line for this joint project. Limex supplied the crate washer and a foam disinfection unit, and VHM automated the corresponding logistics and handling processes. The seed breeder that assigned the project uses Menno Florades as a disinfectant to thoroughly disinfect the crates after washing. Limex has developed special foaming equipment for this specific disinfectant so choosing them to supply the line was an logical decision. Foam disinfectant has a longer contact time on the surface of the crate so the active components can effectively disinfect for longer.

For this project, the customer explicitly requested an integrated washing, foaming and automated process. One of the reasons was to reduce labour costs – which is an important consideration in view of the current tight labour market – while improving the ergonomics of stacking the crates, which weigh about 30 kg, was another key factor. Automation also minimises the risk of cross-contamination as there is less human intervention during the process.

And automation is where VHM comes in. VHM provided the initial input and transfer of crates. The crates that have been washed and foam disinfected by the Limex machines are then buffered in 14 stacks of three crates at the end of the line by the VHM component of the processing line. This quickly creates a trailer load of crates ready to be loaded and eliminates the need to manually stack the crates individually.

The combined expertise of Limex and VHM in one automated washing line delivers another benefit for the customer: the assurance that all the crates are washed uniformly and consistently each time. At a time when the sector is severely affected by viruses, including ToBRFV and CGMMV, being able to rely on this performance is key.

Clever configuration

Collaboration throughout the process was excellent according to Joep. “At the design stage of the line we had to factor in the limited availability of space. We used a clever and practical construction and configuration to fit the new line into the available space. VHM proved to be an extremely flexible partner. Both Limex and VHM adapted the line to suit the customer’s needs, but the excellent cooperation has resulted in a robust, single line.”

Projects in the pipeline

The fine cooperation between Limex and VHM will continue after this project with several projects for the two machinery constructors already in the pipeline. “VHM focuses more on outdoor cultivation systems. Limex targets plant growers and processors of fruit and vegetables,” Joep says. “VHM makes a solid partner for the future. By combining our washing and foaming systems with VHM’s automation expertise we aim to take hygiene in horticultural logistics to an even higher level together.”

It’s a win-win situation Rik agrees. “Limex and VHM are active in different sectors, with different machines. Working in partnership unites these diverse markets. By leveraging the expertise of Limex, we can boost the hygiene performance of our lines, and Limex now has access to control technology and automation. It really is a match made in heaven for these two specialists.”

This promising partnership looks set to continue, nationally and internationally. “Together with VHM , we will focus our efforts on international cooperation in the fruit and vegetable and horticultural sectors, particularly in Europe and North America, regions where we both already enjoy a strong market position,’ Joep concludes.