Limex develops process for hygienic cleaning of propagation trays

Helmut Schneider GmbH from Künzelsau Amrichshausen in southern Germany has been active for decades in producing plugs and other products for the agricultural and horticultural sector. At the request of this global player in the horticultural sector, Limex has developed a process to remove fusarium spores, xanthomonas and phytium from seed trays. The process was developed in cooperation with Menno Chemie Vertrieb GmbH.

Search for guaranteed hygiene

Every year, Helmut Schneider sells millions of plugs to nurseries in Germany and abroad. It goes without saying that hygiene during cultivation and transport is crucial to produce healthy crops in the end. In particular, preventing fusarium spores, xanthomonas and phytium have high priority. These microorganisms are familiar threats to healthy cultivation and are common in agriculture and horticulture. Nurseries are becoming increasingly vulnerable due to increasing scale, specialisation and globalisation. Because of this, growers and traders set ever-greater demands on their suppliers. In its search for a way to guarantee customers an absolutely hygienic product, Helmut Schneider came to Limex.

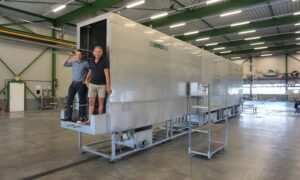

Helmut Schneider has been using Limex tray washers since it was founded. Over the years, the company has exchanged its tray washers for newer and larger models several times to meet the demand for more intensive cleaning. The goal was always the same: adequate cleaning according to the wishes and capacity of the moment. An optimal combination of the right chemicals, enough mechanical power, the right temperature and enough time is very important. These 4 factors vary in each washing phase in the machine.

Controlled process in the tray washer

The process developed by Limex with the support of Menno Chemie Vertrieb GmbH consists of a number of phases. The first is the main wash, which consists of soaking with Menno Hortisept Clean and rinsing. The excess water is then blown off. This is followed by foaming with Menno Florades. This is an important step because it keeps the concentration at an appropriate level at all times and significantly increases the contact duration.

Checking and logging parameters in the tray washer

The tray washer is equipped with a comprehensive control system that monitors, adjusts and stores parameters. Limex and HS Schneider can view the parameters online on a computer or smartphone and use the data logger to review the history. This enables HS Schneider to check that the parameters met the desired values at any time in the past.

Mr Olivier Schneider describes his experience with Limex and the tray washer:

“We’ve been working with Limex for years because we’re happy with the washing machine and the support. Limex is developing constantly to meet our increasingly stringent requirements. We also appreciate that they buy back the old washing machines for a good price. We can recommend Limex with a clear conscience.”

June 2021, Mr Oliver Schneider, Managing Director and successor of Helmut Schneider GmbH